Uncategorized

Peck’s Mills

Onota Brook may look like a quiet, country stream now, but, throughout much of the nineteenth century, the water flowing in its fast moving current powered hundreds of textile machines, operated by close to a thousand workers who annually produced tons of wool and cotton fabric.

The first industry to harness the water power on Onota Brook was not connected with textiles at all, but was an iron forge owned by John Seymour. The early iron forges used the water source to power the large bellows to fan the intense heat needed, and then to drive the hammer that flattened and shaped the iron.

The new technologies to clean, spin and wind cotton and wool fueled such a demand that entrepreneurs across New England looked for sites to set up new factories. Two such entrepreneurs were Elijah and Jabez Peck, brothers who started a tin manufacturing firm in 1828.

In 1844, Elijah Peck bought out the water privileges from Seymour for his first building housing a cotton warp mill that made yarn from cotton fibers for sale to other factories weaving the cloth. This structure was located just west of the junction of Peck’s Road and Onota Street.

Within a year, Peck’s brother Jabez had joined the enterprise and gradually expanded the operations. The new company, J. & E. Peck Manufacturing, continued to grow with new buildings and dwellings for the 75 employees working in his cotton factory before the Civil War. By 1853, both brothers had transferred ownership to the next generation, Jabez L. Peck, who changed the name of the company to J.L. Peck.

The younger Peck had his eyes on another forge further upstream operated by Aaron Hechot and bought it out during the Civil War. His decision to expand may have been driven by the drying up of cotton supplies as a result of the war, but he was also certainly aware of new competition from the Russell brothers building a woolen mill just downstream from his cotton operations.

The large, 2-story brick mill and became known as the Upper Mill, in contrast to the Lower Mill which still produced cotton. Peck had little time to recoup his large investment in the new mill before he had to contend with a fire which gutted his cotton warp factory in 1866. Two years later, though, he had added a new 2-story wood frame building to his lower mill for cotton and continued to expand adding dye-houses, storage boiler rooms for steam powered to supplement water as the energy source for the two mills.

At its height, the company with both mills employed over 300 men, women and children who operated carding machines, narrow and broad looms and thousands of spindles to wind the thread produced. Jabez L. Peck continued running the business well into his 90s, but was succeeded by his son Thomas after he died in 1895 at the age of 96. The mill continued in operation until 1910 when it closed.

Within a year, a new company was organized, Berkshire Woolen and Worsted, that bought the complex and brought in new equipment and expanded the workforce to 450. Berkshire Woolen continued to operate until 1960 when competition from synthetic fibers and southern mills forced it to close.

Today, only Peck’s Upper Mill still stands, at the corner of Valentine and Pecks Roads, along with several of the dwellings that were built to house the workers along Peck’s Road and at the end of Onota Street.

Pomeroy Mills

Another of the earliest mills grew up on the West Branch of the Housatonic, but near the center of the town. Initially called the Pittsfield Woolen and Cotton Company, it was run by members of the Federalist political party in direct competition with another mill under the direction of Democrats, the Housatonic Mill across town, near present-day Elm Street.

The connections of the principal owner, Lemuel Pomeroy, show how close knit this textile manufacturing business was in Pittsfield. For one, Pomeroy was able to draw into his new enterprise in 1814, the well-known inventor, Arthur Schofield who had introduced the first carding machines to Pittsfield (see also Stearnsville.) He hired as his first superintendent, James Colt, who arranged to have the first structures for the mill complex up and running by 1815. Shortly thereafter, Pomeroy turned over the superintendent’s position to Thaddeus Clapp, whose son went on to be President of Pontoosuc Woolen Mill.

The first building, a three-story brick plant with an attic, spanned a distance of 80 feet long and 45 feet wide. Inside ran one of the largest and most profitable woolen operations in the town in the years before the Civil War, employing over 200 men, women and children to run 80 looms.

Pomeroy continued to purchase land and old mills upstream to expand his enterprise. In 1839, he brought his sons into the business and changed the name of his mill to L. Pomeroy & Sons. Only one, Theodore, had the interest in and talent for running such a complex, and he kept the mill operating until his death in 1881. A group of trustees ran the mill before his son came of age and they carried on the business for more than a decade. Still, it was unable to withstand the economic downturns in the 1890s. Helliwell & Co. purchased the mill in 1898 and continued to operate it until 1912. They sold the complex to Eaton, Crane and Pike, whose paper mill was on the other side of the river and was rapidly expanding its business.

The old brick satinet building was torn down in 1904, and the rest of the lower mill was eventually razed. Several buildings of the upper mill complex still stand and house small businesses.

Stanley Electric Manufacturing

It’s hard to imagine now, but, at the end of the nineteenth century, within a few blocks on either side of North Street lay factory buildings that housed the industry that would drive Pittsfield ’s economy for most of the following seventy-five years. The transition of Pittsfield from a town of wool to a city of electricity was breathtakingly fast. The shift saw a new generation of companies and overnight mergers, an influx of innovators, engineers and then thousands of workers, and the rapid construction and relocation of buildings to house the industries capitalizing on the revolution wrought by harnessing electricity.

Electrical lighting came to Pittsfield just a few years following the introduction of street lighting in the United States. The first company to supply electricity to the town was the Pittsfield Electric Light Company in 1883 which had a power station on North Street. A second, rival company was formed a few years later by an innovator who had moved to the county from Pittsburgh where he had been working with George Westinghouse. William Stanley founded the Pittsfield Illuminating Company in 1887 on West Street. The two companies merged in 1890 to form the Pittsfield Electric Company and established its station in a large three-story brick building part of which still stands at the corner of Renne and Eagle Streets. On the upper floor was the laboratory and workshop of William Stanley who had been experimenting for some time with alternating current as a way of delivering electricity across long distances.

Stanley convinced investors to underwrite a company for the laboratory and another one to produce his designs for transformers and generators. He occupied a building near the train station to produce this equipment, which initially hired only 16 men, and then built a larger factory next door. In 1893, he had outgrown his laboratory and had built a large brick factory next to the Pittsfield Electric Company on Renne Street, which employed over 300 people. His two companies – the laboratory and the manufacturing plant – merged under the Stanley Electric Manufacturing Company in 1895.

Competition from other companies nationally required continued and rapid expansion, which the local investors and managers could not sustain. By 1899, the Stanley Electric Manufacturing had been sold to the Roebling Sons Company of New Jersey, who then moved quickly to expand operations. The new owners made plans for a new manufacturing plant in the Morningside section of the city. By 1901, the company had built a brick building 500 feet long by 90 feet wide, surrounded by several accessory buildings. Employment in this new complex reached 1200 people that year. The large buildings on Renne and near the train station that were just ten years old were abandoned.

Just two years later in 1903, the Stanley Electric Manufacturing Company was purchased by a new firm out of New York, General Electric. The changes to the city wrought by William Stanley and the introduction of electricity to Pittsfield came quickly, in a span of not quite 20 years

There is but scant physical evidence of those early years. The factory off of West Street has long since been removed, completed during the urban renewal program in the late 1960s. Along Renne Avenue, though, still stand the original Pittsfield Electric Company station (or at least a part of it) and an office building that now houses the Lichtenstein Center for Arts. In between is a parking lot, where there once was the factory that produced the electrical transformers that changed so much of the way Americans lived and worked.

Berkshire Brewing Association

Pittsfield once had its own brewery, and quite a well-known and lucrative one at that. It was established in 1868 by German immigrants Jacob Gimlich and John White, both of whom were Civil War veterans. Gimlich started out working for Taconic Woolen Mill, but soon joined his brother-in-law White to buy out a small brewery in town. The two launched the Pittsfield Brewery in a small plant at the corner of Columbus Avenue and John Street, where they produced initially about 6 barrels a day.

Their business grew fast, as the only brewery within 50 miles of the town, employing by 1890 one hundred people and producing 300 barrels a day. Their line-up of beers sound like the finest craft beers of today – Lenox Half Stock Ale, Greylock Ale, Mannheimer Lager and India Pale Ale. They soon outgrew their small plant, and built a larger building in 1890, but not far up Columbus Avenue at the corner of Onota Street. Occupying an entire city block, the imposing brick factory measured eighty by forty feet and stood five stories tall. Old maps also indicate that they were able to re-route water under Onota Street to their factory for their brewing purposes. The brothers lived across the street in large houses.

Shortly after building this new brewery, the two founders turned the business over to the next generation who continued to expand. Sales of Berkshire beer reached across New England and as far south as the Carolinas.

Prohibition, passed in 1919, forced the brewery out of business. Many of the buildings on the brewing complex were torn down, but the Siegel Furniture Company bought the bottling plant and converted it into warehouse and showroom space.

The city purchased the site in 1975, perhaps as part of its ongoing, but controversial, urban renewal programs that razed buildings along Columbus Avenue closer to North Street. The housing authority had built the complex of apartment units which currently occupy the block.

Kellogg Steam Power Company

This three-story brick structure in Morningside may be the Kevin Bacon of Pittsfield’s mills: through only a couple degree of separation, its connections reach many of the other mills and companies in the town and in this study.

It was the nature of this business that gave it such a far reach. The company was formed in 1874 to provide power for its tenants, mostly smaller businesses. Innovators and entrepreneurs needed such a service since water privileges along Pittsfield’s many streams were locked up by larger mills. The move towards power harnessed from coal allowed the Kellogg Steam Power Company to locate away from water and close to the Boston and Albany Railroad line for easy access to shipping.

Ensign Kellogg put together the group of investors for their idea to provide space and steam to smaller entrepreneurs. Kellogg was a major business and civic leader in Pittsfield serving as President of the Pontoosuc Woolen Mill and the Agricultural National Bank during the Civil War. He served several terms in the Massachusetts legislature and as a delegate to the Republican National Convention that nominated Abraham Lincoln for President.

Kellogg Steam Power helped launch many enterprises in the town, who leased space and then moved on to acquire their own buildings. On the first floor was the Pittsfield Tack Company, under the direction of Jabez L. Peck (of Peck’s mills) that employed 25 operatives to manufacture nails, brads and – you guessed it – tacks. Saunders Silk Manufacturing took over the third floor and then left to merge and establish the A.H. Rice Silk Company. Farrell and May shoe manufacturers were tenants, as was the Terry Clock Company which occupied the second floor until it moved to its new premises in 1884. It was here that George Bliss, the entrepreneur whose invention of a device that could transmit telephone signals through clocks helped propel the nationwide sales of the Terry Clock Company, located in the town center. By the turn of the century, with the advent of electrical power in Pittsfield, the need for steam power declined. The Musgrove Knitting Company bought the building and ran its operations there until the 1940s. Now it serves as a retail furniture business.

One of the better preserved nineteenth century factory buildings in Pittsfield, the building is almost 200 feet long and is distinguished by its two square towers, with hip roofs. Decorative brick patterns at the cornice where the roof and the walls meet and original windows can be seen here at the juncture of Curtiss and Kellogg Streets in Morningside.

Taconic Woolen Mill

Before the Civil War, the profitability of woolen mills meant that every conceivable site along a falling river was re-purposed to house the new industrial machinery for carding, spinning and weaving wool. In 1856, the brothers George and Edward Learned launched Taconic Mill on the western branch of the Housatonic, wedged between two other mills: the Pontoosuc Woolen Mills upstream and the Pittsfield Woolen Mill downstream. The site they chose had been a musket shop owned by Lemuel Pomeroy (who had started his own woolen mill in the center of the city.)

The original building was a large wooden structure measuring 150 feet by 50 feet and four stories high. The choice of wood material ran counter to the trend since most of the mills in the city were of brick construction by mid-century, better able to withstand fire. The company ran a brisk business through the Civil War, employing over 150 operatives to produce 450,000 yards of woolen cassimere (a soft wool like cashmere.)

Perhaps the Learneds had too many financial interests (including silver mining near Lake Superior and a railroad across Mexico) as they shut down operations for seven years in 1873, the same year as a financial panic across the nation. Then, James Wilson leased the mill and later purchased it outright with a series of successive partners and sporadic shutdowns due to recurring panics in the late 1800s. During this time, Wilson and his partner Arthur Horton bought out the mill downstream, then known as Bel-Air manufacturing.

One of the most unique structures ever seen in Pittsfield was the office building that James Wilson had built in the 1890s. With a wrap-around porch and a hip roof with dormers, the shingled house resembled a country lodge and stood at the front of the complex of brick and wooden structures.

The mill stayed in operation until 1927, and slowly the buildings were razed. One of the last remaining structures was the office building that was destroyed by fire in 1981. The only building still standing today is a square, two-story brick building with a brick smokestack that may have served as a boiler room powering the entire complex.

Pittsfield Woolen Mill/Bel-Air

The sign on the chain link fence warns against entry because of high levels of lead and arsenic. All that is visible is a concrete slab, outlining what was the main mill building of the Pittsfield Woolen Mill. On either side of the fenced off property are the remains of two of the out-buildings. Other traces that this was once one of the thriving manufacturing “villages” in Pittsfield are the bridge over the Housatonic and the worker houses within walking distance. The dam just to the north of the mill re-directed water into the canal to power the carding machines and looms operated by 100 employees before the Civil War.

Henry Colt, the son of a Massachusetts judge, founded the company in 1852 and took over an abandoned building downstream from two other woolen mills on the West Branch of the Housatonic. Colt had built a large stone dam that captured more water power for the production of “cassimere” cloth, a fine woolen twilled cloth akin to cashmere. Working with wool produced sparks, and, the older buildings were particularly susceptible. In 1861, fire did break out in the mill and destroyed the upper floors before recruits for the Tenth Regiment of Massachusetts Volunteers awaiting deployment for the Civil War rushed from their training camps across the street to extinguish the fire.

After the war, in 1873, the company was bought out by Bel-Air Manufacturing and continued to operate under that name until 1884. These buildings were then taken over by Wilson and Horton, new owners of the Taconic Mills, a neighboring, upstream mill. Wool continued to be produced in these buildings until 1927.

Maps from the late 1800s show the main building separated into the functions of carding, weaving, burling (removing the small knots of wool in the fabric,) spinning and dyeing as well as outbuildings for storage and an office. Across the river were a store and dwellings along Wahconah Street belonging to the company for workers.

In the late 1920s, Hathaway Bakeries bought the mill and used the largest building for its own flour operations. By the 1950s, the complex was used for storage as well as a bottling company for Nehi, 7-Up and Royal Crown Soda. Later owners included Goodwill Industries and Ski America.

Two fires destroyed the largest structures, the first in 2001 and the second, four years later. In 2008, the Berkshire Brownfields Program received funding from the EPA to clean up contamination at the site.

Now, the two buildings that remain on either side of the fenced off slab that housed the bakery continue to function as residences and a place of business.

S.N. & C. Russell Manufacturing

The Russell brothers –Charles, Franklin, Hezekiah and Solomon N. – moved to Pittsfield as young boys with their family in 1822, just as the town started to shift from an economy based on farming to manufacturing. In 1845, they bought a small factory for carpenters’ tools that stood on the site of what was once an iron forge on Onota Brook that fed into the western branch of the Housatonic River. They converted this small building for the production of cotton batting which we know as the soft fabric that quilters use as a layer under the patchwork.

It was likely the impact of the Civil War on the cotton-producing states that drove the brothers to build on these same premises a new three-story woolen mill in the middle of the Civil War. The demand for wool, especially from government contracts for uniforms and soldiers’ blankets, proved large enough to support another woolen mill in the town. With new equipment, the Russells were able to capture a significant size of the wool production, employing over 125 people in the years following the Civil War.

By all accounts, the Russell brothers were both colorful and charitable with their fortune. Solomon became active in city government; in his will, he left the land on North Street for the House of Mercy, the precursor to the hospital in the same location. Hezekiah left Pittsfield on an 8-year adventure that took him out west and then on to a detour to Australia and back through Europe to return to Pittsfield to help out in the family business.

Despite such peripatetic interests, the Russell mill was a going concern with a workforce of 250 at its peak in the late 1800s, but the deaths of the brothers led to a selling off of assets in 1941 to Kinney Woolen and Worsted Yarn and then to Elmvale Worsted Company. The building continued to function as a woolen mill until 1960, one of the last woolen operations in the county.

Russell Mill stands south of Pecks Road on Onota Brook and across the street from the Catholic Cemetery. The mill has been successfully readapted as a warehouse and retail outlet for fabrics. Its main building features many unique design elements, including a prominent stair tower off-center on the front façade and arched lintels on the recessed windows, with multiple outbuildings for a machine shop, a store and warehouse. The presence of two other mills on Onota Brook made for a populated settlement with sufficient tenement housing for the large workforce, some of which still stand.

See also: Russell Family Values, by Tony Drowolski

The Barker brothers and their village

Success has many imitators, and the young woolen industry in Pittsfield by the 1830s spawned a number of aspiring entrepreneurs

who were eager to stake out their spot on any one of a number of fast moving rivers around the town. In 1832, John Barker and his brothers, Charles and Otis, bought the mill that Daniel Stearns built on the stream leading into the western branch of the Housatonic. They converted it for the production of satinet, a finely-woven cloth resembling satin but using both wool and cotton.

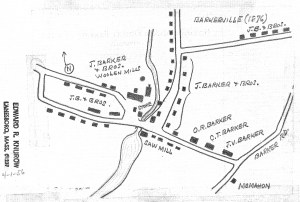

The brothers moved quickly to expand and two years later had built a three-story brick mill 150 feet by 65 feet, one of the largest buildings in the town. New buildings went up quickly: the village bearing their name converged at the intersection of four roads around which were multiple tenement dwellings for workers, a store, a saw mill and three duplicate neighboring Italianate villas for each of the brothers. Because of the distance from the town, many of the 230 workers lived in the village and operated the 84 looms. By the 1850s, J. Barker & Brothers produced more wool and cotton than any other factory in Pittsfield.

Their success allowed them to buy out D.H. Stearns at the end of the Civil War, prompting the new mill village to assume the name “Lower Barkerville.” This village occupied 70 acres on which stood two large stone factories and groupings of employee houses.

The demise of the Barkers’ concern came quickly, in part due to overreach and the business cycle, but also as a result of a spectacular fire in January 1879 in Lower Barkerville that gutted one of the main factory buildings. In just ten years, the company’s demise was complete. The factory buildings were dismantled and many of the dwellings disappeared.

Today, at the junction of Cloverdale, Branch and Church Streets, newer homes have replaced the factory buildings and worker housing. What does remain is one of the brothers’ villas at the beginning of Cloverdale. The quiet of this neighborhood on the southwest end of town is broken only by the sound of the stream that once powered the mills and the occasional airplanes flying in and out of the nearby Pittsfield airport.

See also: The blaze that burned Barkerville, by Judy Waters

Stearnsville – Present at the Creation

By the middle of the nineteenth century, the largest and one of the oldest mills operating in Pittsfield was D & H Stearns, just east of Hancock Shaker Village. Yet, today, there’s nothing except a small settlement of houses to indicate that this was Stearnsville, once a bustling, prosperous mill village, dating back to the first years of the 19th century.

The streams that flow into the south west branch of the Housatonic River had enough of a fall to serve as an ideal power source for several mills, in both directions, including the earliest Shaker flour and grist mills just upstream at Hancock Shaker Village.

When Daniel Stearns moved to Pittsfield from Connecticut in 1801, he purchased a mill on this stream that was essentially used just for dressing, fulling (cleaning) and dying the wool that had been carded (cleaned and disentangled) by hand in the homes around the town. Machinery for carding or spinning wool had not been invented.

A few years later, Arthur Schofield, an entrepreneur/inventor, left England with drawings of a carding machine and spinning Jenny. He set up shop in Pittsfield on West Street to produce these machines. One of his first customers was Daniel Stearns who purchased a spinning Jenny and 24 spindles from Schofield in 1810. A year later, Stearns had built a “New Woolen Factory” to house the operation and two of his machines. When Schofield perfected a machine to card the wool, Stearns installed this innovation in his factory in 1812. This revolutionized the industry, opening the way up for new mills throughout the county, which produced more wool than any county in the U.S. by the 1850s.

By then, though, Daniel Stearns had passed his company on to his four sons, who continued to expand the operations along this branch of the river, replacing the original wood factory with larger brick buildings and updated machinery. At its height, the company commanded five different factories, 30 dwellings for its workers on 45 acres of land and even a small church, Emanuel Chapel, affiliated with St. Stephen Episcopal Church on Park Square. By the end of the Civil War, the brothers had started selling off pieces of their settlement, and the lucrative water rights. In turn, these became going concerns established downstream on the same branch of the Housatonic under the management of J. Barker & Brothers and Tillotson & Collins. (see Barkerville) A fire destroyed one of the remaining factory buildings, but it was the increased competition and a recession which eventually proved fatal for Stearns. In 1881, D & H Stearns Company which still owned just one factory announced its failure and closed its operations. The equipment from the mill was sold and transferred to Bel-Air mills on Wahconah Street on the other side of Pittsfield.

What’s left of Stearnsville? There’s a school, Stearns Elementary, on Lebanon Avenue, which connects with West Housatonic (Rte 20.) There’s also enough of a meandering river to hint that once there were two and three story buildings dominating the landscape and calling men, women and children to its doors six days a week.

- ← Previous

- 1

- 2

- 3

- Next →